Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

3D Printing of Optical Components: A Revolutionary Breakthrough in the Field of Optical Sciences - Springer In Optical Sciences 233

The Rise of 3D Printing

Over the past decade, 3D printing technology has evolved and grown at an astronomical rate. Initially used primarily for rapid prototyping, this innovative technology has now expanded its horizons to various industries, including healthcare, automotive, aerospace, and fashion. Among these industries, the field of optical sciences has witnessed a remarkable revolution with the advent of 3D printing of optical components.

What is 3D Printing of Optical Components?

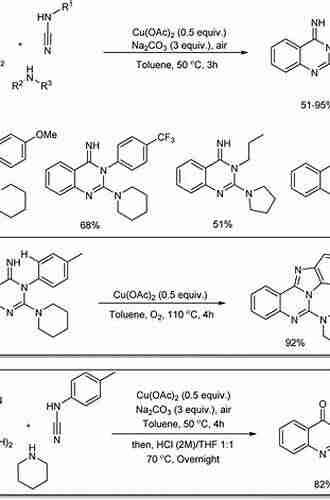

3D printing of optical components refers to the process of fabricating optical elements using additive manufacturing techniques. Traditional manufacturing methods for optical components involved complex and expensive processes, such as grinding, polishing, and coating. However, 3D printing eliminates many of these limitations by allowing the creation of intricate optical designs directly from digital models.

The use of 3D printing in optical sciences enables researchers, engineers, and scientists to produce customized optical components with unprecedented precision and complexity. By harnessing the power of digital modeling and advanced printing techniques, optical components that were once considered impossible to manufacture are now being produced with utmost efficiency.

5 out of 5

| Language | : | English |

| File size | : | 59045 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 538 pages |

Advantages of 3D Printing of Optical Components

The utilization of 3D printing technology in the fabrication of optical components brings numerous advantages. One of the significant advantages is the freedom of design. Traditional manufacturing methods often impose limitations on the complexity and shapes of optical components. With 3D printing, intricate and unconventional geometries can be easily produced, opening up new possibilities for optical device design and performance optimization.

Another advantage is the reduction in cost and time. 3D printing eliminates the need for specialized tooling and the associated costs, making it a more affordable option for prototyping and small-scale production of optical components. Additionally, the speed at which optical components can be produced using 3D printing significantly reduces the time required for the manufacturing process, accelerating research and development cycles.

Applications in Optical Sciences

The applications of 3D printing in optical sciences are vast and versatile. One of the most notable applications is in the field of optics and photonics research. Researchers can now quickly prototype and test new optical designs, enabling rapid advancement in the development of optical devices and systems. This has the potential to revolutionize industries such as telecommunications, medical imaging, and solar energy.

Furthermore, 3D printing allows for the fabrication of complex optical components with integrated functionalities. For example, micro-optical systems with lenses and waveguides can be printed as a single monolithic structure, eliminating the need for assembly and alignment. This not only simplifies the manufacturing process but also enhances the performance and reliability of the optical systems.

Challenges and Future Outlook

Despite the numerous advantages, 3D printing of optical components also comes with its own set of challenges. Achieving high surface quality is one of the primary challenges faced in this field. Optical components demand extremely smooth surfaces to minimize light scattering and ensure optimal performance. Developing printing techniques and materials that can provide the required surface finishes is an ongoing area of research.

However, with continuous advancements in printing technologies, material sciences, and computational modeling, the future outlook for 3D printing of optical components is incredibly promising. It has the potential to redefine the way optical components are designed, manufactured, and integrated into various applications.

The revolution brought about by 3D printing of optical components in the field of optical sciences is undeniable. It offers new avenues for innovation, customization, and cost-effectiveness. As researchers and scientists continue to push the boundaries of what is possible with 3D printing, we can expect to witness even more groundbreaking developments in the field. The Springer In Optical Sciences 233 publication showcases the latest research and advancements in 3D printing of optical components, making it an essential resource for anyone interested in this revolutionary technology.

5 out of 5

| Language | : | English |

| File size | : | 59045 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 538 pages |

This edited volume reviews the current state of the art in the additive manufacturing of optical componentry, exploring key principles, materials, processes and applications.

A short lets readers familiarize themselves with the fundamental principles of the 3D printing method. This is followed by a chapter on commonly-used and emerging materials for printing of optical components, and subsequent chapters are dedicated to specific topics and case studies. The high potential of additive manufactured optical components is presented based on different manufacturing techniques and accompanied with extensive examples – from nanooptics to large scale optics – and taking research and industrial perspectives. Readers are provided with an extensive overview of the new possibilities brought about by this alternative method for optical components manufacture. Finally, the limitations of the method with respect to manufacturing techniques, materials and optical properties of the generated objects are discussed.

With contributions from experts in academia and industry, this work will appeal to a wide readership, from undergraduate students through engineers to researchers interested in modern methods of manufacturing optical components.

Samuel Ward

Samuel WardTake Control Of Your Network Marketing Career

Are you tired of working...

Bryson Hayes

Bryson HayesThe Enigmatic Talent of Rype Jen Selk: A Musical Journey...

When it comes to musical prodigies,...

Norman Butler

Norman ButlerUnveiling the Rich History and Poetry of Shiraz in...

When it comes to the cultural...

Cade Simmons

Cade SimmonsHow Impatience Can Be Painful In French And English

: In today's fast-paced world, impatience...

William Shakespeare

William ShakespeareSewing For Sissy Maids - Unleashing Your Creative Side

Are you ready to dive...

Harry Hayes

Harry HayesGST Compensation to States: Ensuring Fiscal Stability...

In the wake of the COVID-19 pandemic,...

Rodney Parker

Rodney ParkerLearn How to Play Blackjack: A Comprehensive Guide for...

Blackjack, also known as twenty-one, is one...

Wade Cox

Wade CoxComplete Guide Through Belgium And Holland Or Kingdoms Of...

Welcome, travel enthusiasts, to a...

Jack Butler

Jack Butler15 Eye Popping Projects To Create with Felt Decorations

Felt decorations have become a popular craft...

Dennis Hayes

Dennis HayesFirst Aid For Teenager Soul Mini Book Charming Petites...

The teenage years can...

Brett Simmons

Brett SimmonsFrom Fear To Freedom - Overcoming Your Fears and Living a...

Are you tired of living in...

Carl Walker

Carl WalkerSmoking Ears And Screaming Teeth: The Shocking Truth...

Smoking has long been known to cause a host of...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Keith CoxFollow ·19.5k

Keith CoxFollow ·19.5k Isaac MitchellFollow ·17.5k

Isaac MitchellFollow ·17.5k Guillermo BlairFollow ·15.7k

Guillermo BlairFollow ·15.7k Junichiro TanizakiFollow ·16.4k

Junichiro TanizakiFollow ·16.4k Ed CooperFollow ·14k

Ed CooperFollow ·14k Brent FosterFollow ·2.1k

Brent FosterFollow ·2.1k David PetersonFollow ·8.2k

David PetersonFollow ·8.2k Bryson HayesFollow ·9.9k

Bryson HayesFollow ·9.9k