Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

World Class Manufacturing Including Lean Six Sigma Kanban And Checklist

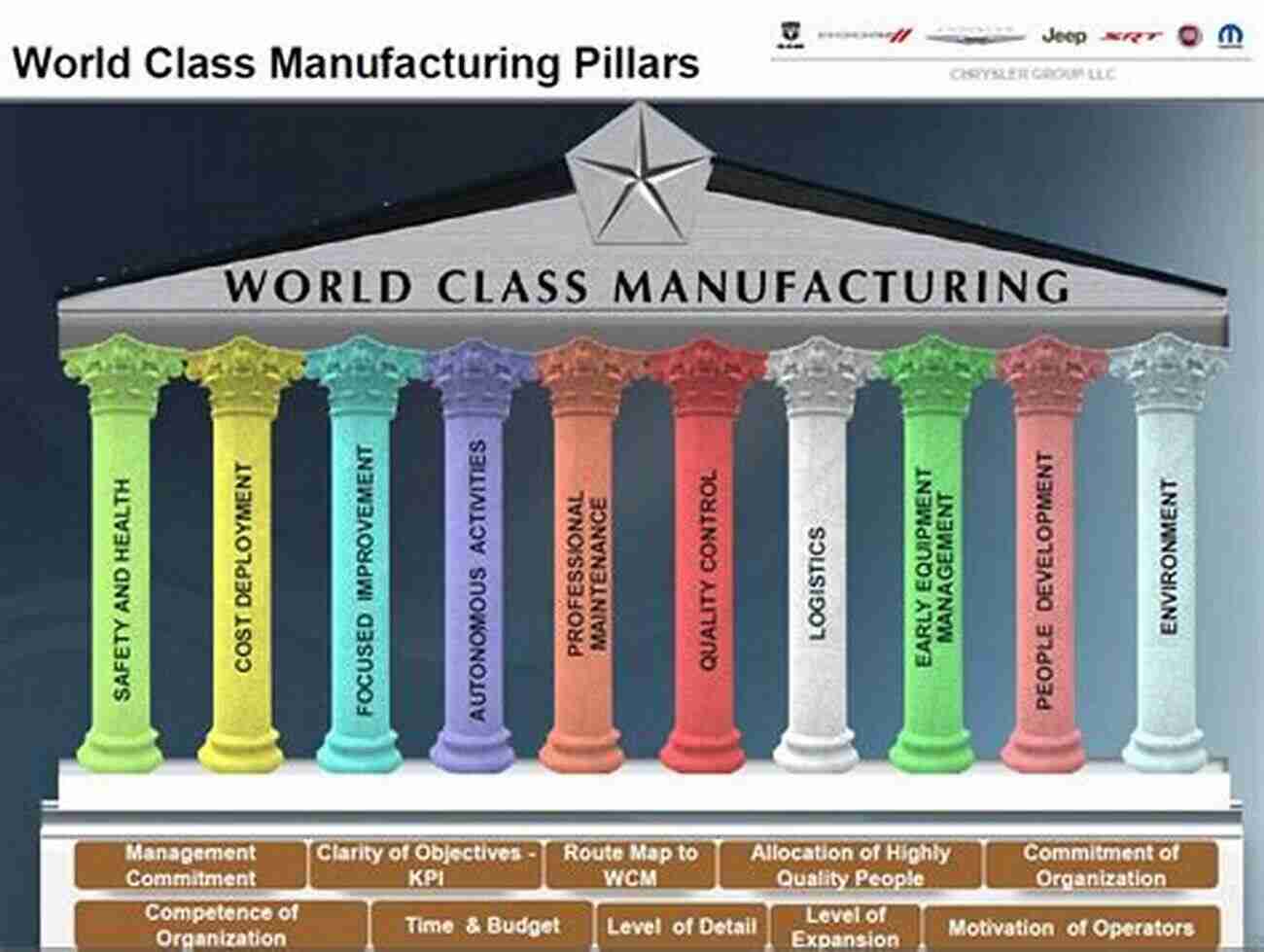

Manufacturing processes play a crucial role in the success of any business organization. To achieve world-class manufacturing standards, companies need to implement effective methodologies and strategies that streamline operations, reduce waste, and improve overall efficiency. In this article, we will explore three key concepts that contribute to world-class manufacturing: Lean Six Sigma, Kanban, and Checklist.

Lean Six Sigma

Lean Six Sigma is a methodology that combines the principles of Lean Manufacturing and Six Sigma, aiming to eliminate defects and improve process efficiency. Lean principles focus on waste reduction, while Six Sigma focuses on reducing process variability. The combination of these two methodologies results in a powerful approach to manufacturing optimization.

The core philosophy behind Lean Six Sigma is to identify and eliminate waste in all its forms: defects, overproduction, waiting time, inventory, unnecessary motion, transportation, and extra processing. By removing these sources of waste, companies can achieve significant improvements in quality, productivity, and customer satisfaction.

4.5 out of 5

| Language | : | English |

| File size | : | 862 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 116 pages |

| Lending | : | Enabled |

Kanban

Kanban is a visual management tool that helps in the smooth flow of materials and information across the production process. It promotes a just-in-time (JIT) production system, reduces inventory levels, and enables efficient production planning.

Using Kanban, manufacturers can establish a pull-based system where production is triggered by actual customer demand. This approach minimizes waste associated with overproduction and excessive inventory, ensuring that resources are utilized efficiently. By visually representing the workflow and using Kanban cards, teams can easily track the progress of work and identify bottlenecks for timely resolution.

Checklist

A checklist is a simple yet powerful tool that helps in ensuring consistency, quality, and adherence to established standards in manufacturing processes. It acts as a step-by-step guide for operators, providing them with a clear sequence of tasks to be performed and facilitating error prevention.

Checklists help to standardize processes and minimize the risk of defects or omissions. By following a checklist, operators can avoid costly mistakes, reduce rework, and deliver products that meet customer expectations. Furthermore, checklists provide a valuable documentation tool that aids in process improvement and knowledge transfer.

Implementing World-Class Manufacturing

To implement world-class manufacturing practices, organizations need to integrate Lean Six Sigma, Kanban, and Checklists into their existing workflows. Below are some key steps to follow:

- Assess Current Processes: Analyze current manufacturing processes to identify areas of improvement and waste.

- Train Employees: Provide comprehensive training on Lean Six Sigma principles, Kanban systems, and Checklist usage.

- Implement Lean Six Sigma: Apply Lean Six Sigma methodologies to continuously improve processes, reduce defects, and optimize productivity.

- Introduce Kanban: Implement a visual Kanban system to enable just-in-time production and enhance workflow visibility.

- Create Checklists: Develop checklists tailored to specific processes, ensuring standardized operations.

- Periodically Review and Refine: Continuously monitor the effectiveness of implemented strategies and make necessary adjustments.

World-class manufacturing requires a commitment to excellence and a systematic approach to process improvement. By integrating Lean Six Sigma, Kanban, and Checklists into their manufacturing processes, organizations can achieve substantial benefits, including enhanced productivity, reduced waste, improved quality, and increased customer satisfaction. Implementing these methodologies requires diligent planning, training, and ongoing evaluation, but the rewards are well worth the effort. Take your manufacturing operations to the next level by embracing world-class practices today!

4.5 out of 5

| Language | : | English |

| File size | : | 862 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 116 pages |

| Lending | : | Enabled |

World class manufacturing is the key to achieving shorter lead times, lower inventory and on time in full delivery performance, measured in misses per million! This e-book will start by looking at best practice in traditional manufacturing practices before moving on to look at techniques under headings such as Lean Manufacturing, Just in Time, Total Quality (including Six Sigma) and so on (see contents list below). The book also contains the well established 20 point World Class Manufacturing checklist which enables you to check how you compare with the best in class and helps identify both opportunities for improvement and progress.

Phil joined Knowles Electronics as Production Manager. Over the 10 years period whilst he was the project leader in their Business Excellence programme, Knowles had achieved class "A" in MRPII, reduced lead times from 8 weeks to next day kanban deliveries, reduced inventories by one third, achieved a better than 99.5% on-time delivery record and reduced customer returns to less than 300 parts per million using many of the techniques described in this book.

After leaving Knowles Phil worked with MRP Ltd and also set up his own consultancy BPIC.

Contents: Managing traditional work orders and work to lists, kanban, continuous improvement principles, task forces, set-up time reduction, workplace layout and "U" shaped lines, Business Process Reengineering, point of use storage, housekeeping and 4s, statistical process control and 6 sigma, built in quality, cross training, preventative maintenance, team working and Kaizen.

Samuel Ward

Samuel WardTake Control Of Your Network Marketing Career

Are you tired of working...

Bryson Hayes

Bryson HayesThe Enigmatic Talent of Rype Jen Selk: A Musical Journey...

When it comes to musical prodigies,...

Norman Butler

Norman ButlerUnveiling the Rich History and Poetry of Shiraz in...

When it comes to the cultural...

Cade Simmons

Cade SimmonsHow Impatience Can Be Painful In French And English

: In today's fast-paced world, impatience...

William Shakespeare

William ShakespeareSewing For Sissy Maids - Unleashing Your Creative Side

Are you ready to dive...

Harry Hayes

Harry HayesGST Compensation to States: Ensuring Fiscal Stability...

In the wake of the COVID-19 pandemic,...

Rodney Parker

Rodney ParkerLearn How to Play Blackjack: A Comprehensive Guide for...

Blackjack, also known as twenty-one, is one...

Wade Cox

Wade CoxComplete Guide Through Belgium And Holland Or Kingdoms Of...

Welcome, travel enthusiasts, to a...

Jack Butler

Jack Butler15 Eye Popping Projects To Create with Felt Decorations

Felt decorations have become a popular craft...

Dennis Hayes

Dennis HayesFirst Aid For Teenager Soul Mini Book Charming Petites...

The teenage years can...

Brett Simmons

Brett SimmonsFrom Fear To Freedom - Overcoming Your Fears and Living a...

Are you tired of living in...

Carl Walker

Carl WalkerSmoking Ears And Screaming Teeth: The Shocking Truth...

Smoking has long been known to cause a host of...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Gerald BellTo Heal To Train To Entertain - The Power of Entertainment in the Healing and...

Gerald BellTo Heal To Train To Entertain - The Power of Entertainment in the Healing and...

Salman RushdieWhat Every Executive Wants You To Know About Successfully Selling To The Top

Salman RushdieWhat Every Executive Wants You To Know About Successfully Selling To The Top Howard BlairFollow ·15.5k

Howard BlairFollow ·15.5k Robert Louis StevensonFollow ·4.2k

Robert Louis StevensonFollow ·4.2k Gary CoxFollow ·15.8k

Gary CoxFollow ·15.8k Neil ParkerFollow ·7.2k

Neil ParkerFollow ·7.2k Mark MitchellFollow ·4k

Mark MitchellFollow ·4k Marvin HayesFollow ·7.4k

Marvin HayesFollow ·7.4k August HayesFollow ·13.5k

August HayesFollow ·13.5k Anton ChekhovFollow ·6.7k

Anton ChekhovFollow ·6.7k